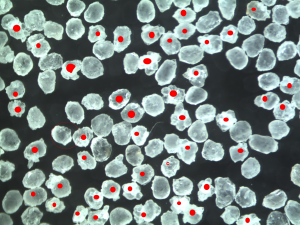

Sand clusters are formed when smaller sand particles or fines are cemented to each other, and then often cemented to a large sand particle. These clusters are commonly formed when in a sandstone formation, but even loose sand deposits can have some cementing and clusters.

Frac sand has to perform downhole under tremendous pressure, and under pressure the clusters “blow up,” breaking apart into the smaller particles and fines. This results in poor performance. We have seen it time and time again in the lab with crush resistance testing – the frac sand crush test performance goes up dramatically as the number of clusters approaches 0%.

So, when hiring a lab to test your sand, it is of utmost importance for your sand sample to be cleaned of clusters. The American Petroleum Institute recommends that “the sand should not be considered suitable if it contains 1 percent or more by count of clusters of multiple sand grains.” (Reference: API Recommended Practice 56 – Recommended Practices for Testing Sand Used in Hydraulic Fracturing Operations).

If you are headed towards frac sand production, you can acquire large industrial scale attrition scrubbers. The key to attrition scrubbing is creating a “pulp on pulp action” where the flows of sand and water (or in some cases acid-water) flow against each other, and the sand is in a way sandblasting itself and removing the clusters.

How do you create this counter opposed flow?

You can think of two blender blades next to each other – or with one inverted over the other – operating in reverse directions. Then there will be a “collision” of sand and water streams as the blades each send their own mixtures at the other. It’s not really the blade itself removing the clusters, but the sand-on-sand action!

We recreate the industrial scrubbing action as best we can here in the lab – on a much smaller scale.

Instead of tons of sand, we typically deal with 400-500 grams of sand per batch, and put our scrubbers on high. We sometimes add acid to the mix to help break down the cement.

Then we wash your sand again (removes any smaller than 200 mesh fines), dry it, and then take a good luck under the microscope.

If clusters remain, we do the process again. By now we have the process fine tuned, though and can estimate our scrubbing times accurately.

Sure, this scrubbing trial and error might cost you a bit more in testing (at least $150 per sample, at the time this post is written), but your material will perform much better.

And that’s a main tenet of our approach to client work here at the lab – enhance your material as best we can (using good engineering and laboratory practices) so your material performs as best as it can.

Check out our other social media pages!